Yogi Magnetite Iron Ore Project

Our Projects

Yogi Magnetite Iron Ore Project

We strive to enhance the quality of life and promote economic sustainability by responsibly developing Australia’s abundant mineral resources through innovation, with a focus on environmental and social responsibility.

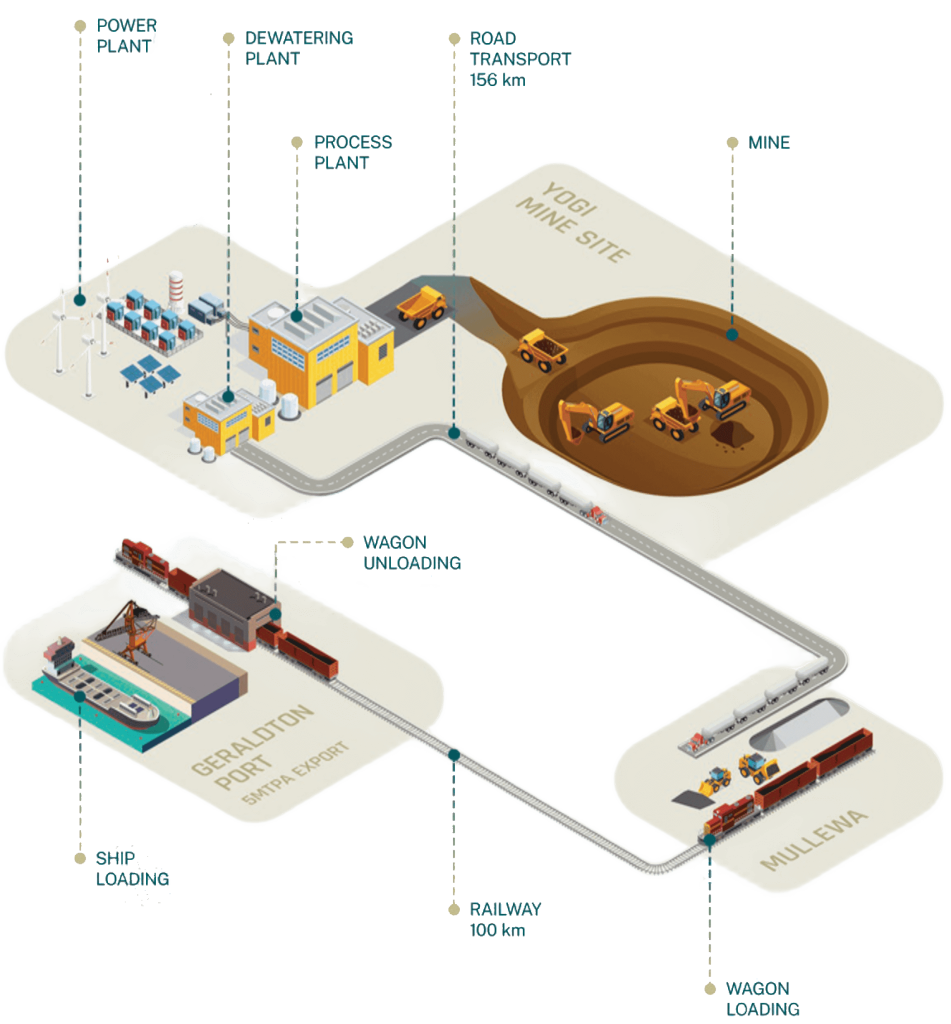

The Yogi Magnetite mine project in Western Australia is a comprehensive undertaking spanning various crucial elements. it accommodates the power plant and associated infrastructure, ensuring the smooth operation of the plant throughout the anticipated 20-year lifespan of the Yogi Iron Ore mine.

The Yogi magnetite mine boasts an approximate life of mine (LoM) duration of 16 years, generating magnetite concentrate at a rate of 5 million tons per annum (Mtpa). Additionally, the mine site encompasses the Yogi Village project, which aims to provide a comprehensive solution for accommodating up to 900 personnel. This all-encompassing project includes labor, materials, equipment, furniture, and decorative accessories, with the goal of creating a well-equipped village that efficiently caters to the needs of the staff.

Mine

The Yogi magnetite mine has a life of mine (LoM) of approximately 16 years. The Project will produce magnetite concentrate at a rate of 5 Mtpa. The mine will deliver ore at a rate of 20 Mtpa dry (nameplate capacity) to achieve the targeted concentrate production.

The Mineral Resource estimates presented were derived from a mineral resource model created on 20 January 2021. After validation and reporting, the mineral resource model is considered to support the Mineral Resource estimates for the Yogi magnetite deposit as of 1 December 2020. The Mineral Resource Estimates are classified in accordance with the JORC Code by SRK (2012).

Yogi Village

The Yogi Village project aims to provide a comprehensive solution for accommodating up to 900 personnel. This project encompasses various aspects, including labor, materials, equipment, furniture, and decorative accessories. The goal is to create a well-equipped village that meets the needs of the staff efficiently.

The scope of the project includes engineering, design, manufacturing, shop assembling, quality assurance, testing, documentation, identification, packing, and the supply of accommodation buildings and facilities. The Administrating Area serves as the central hub for accommodating our FIFO (Fly-In-Fly-Out) staff. It provides a welcoming space for them and serves as their temporary home during their time on-site.

In addition to the accommodation areas, the Yogi Village project also comprises Semi-Industrial facilities. These facilities are designed to cater to various activities such as engineering, safety, and mining. They are equipped to support the project’s requirements and ensure a seamless operation.

When it comes to construction materials, sustainability and environmental friendliness are of utmost importance. All the materials used in the project are carefully selected to have a minimum impact on the environment. They are built to be durable, ensuring that the structures can withstand various loads, including dead and live loads, earthquakes, wind, snow, and more. The goal is to design the foundation and structural frames in such a way that they can stand for a minimum of 20 years.

Process Plant

The Process Plant is composed of various units working together to process materials while managing the waste products. These units include Crushing and Stockpiling, Reclaiming, Dry grinding, Dry Cobbing, primary and secondary Grinding, primary and secondary Magnetic Separation, Tertiary grinding, Magnetic flotation, final Magnetic Separation, Tailing dewatering and Water recovery.

The process starts with crushing and stockpiling, followed by various stages of grinding and magnetic separation. After grinding, the materials are processed through a dry magnetic Cobbing system, where the concentrate is separated from the tailings.

The concentrate then goes through primary and secondary grinding, as well as primary and secondary magnetic separation, to further refine the product. The resulting concentrate is then subjected to magnetic flotation cells, where it is further reduced and the silica content is separated. The tailings from each stage of the process are sent to tailing thickeners to remove excess water. The thickened tailings are then dewatered and transferred to a tailing stockpile. Iron concentrate pumps from Yogi to Mullwa through a slurry pipeline. In the Mullewa, the dewatered and dry concentrate transfer by railway to the Port of Geraldton.

The extracted water is pumped through a pipeline to Yogi and used as recovered water in the process plant. On the other side of the Plant, thickeners and tanks are placed for the purpose of water recovery, which is again distributed to different parts of the process line. The thickened tailings are dewatered and transferred to a tailing stockpile.

Power Plant

The Yogi Magnetite mine project is set to be in Western Australia and will encompass several key components. To accommodate the power plant and its associated infrastructure, a total area of 125 hectares has been allocated. This space will allow for the development and operation of the power plant for the anticipated 20-year lifespan of the Yogi Iron Ore mine.

In terms of infrastructure and utilities, the project will include suitable living arrangements for both long-term operational requirements and construction needs.

For power generation and reducing our carbon footprints, the plant will consist of various components aimed at diversifying energy sources. Gas generators, wind turbines, solar farms, and BESS (Battery Energy Storage Systems) will all be incorporated into the power plant. To monitor and control the power generation and distribution systems, a Micro Grid Intelligent Monitoring Platform System along with a Supervisory Control and Data Acquisition system will be utilized.

The requested power plant aims to meet the power demands of the entire production line, including utilities, the Yogi Village, semi-industrial sites, and off-site buildings. It will need to provide continuous power supply throughout the year, 24/7.

In terms of infrastructure and utilities, the project will include suitable living arrangements for both long-term operational requirements and construction needs.